Molecular Sieve Series

Molecular sieves are a series of porous materials, primarily zeolites, used for adsorption and separation processes based on molecular size and polarity. They are widely applied in industries such as petrochemicals, gas processing, electronics, and environmental control due to their high selectivity and capacity.

Product Details

Product Features

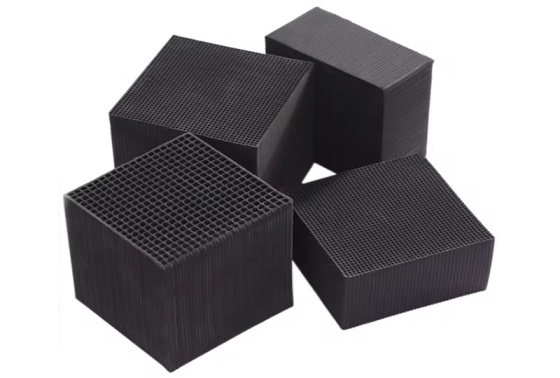

The main material of honeycomb molecular sieve is natural zeolite, which is an inorganic microporous material composed of sio2 /al2o3 and alkaline metal or alkaline earth metal. Its inner pore volume accounts for 40-50% of the total volume and its specific surface area is 300-100m2 / g. It has the characteristics of high temperature resistance, nonflammability, good thermal stability and hydrothermal stability, it is a kind of inorganic microporous material with good adsorption performance and no secondary pollution. the high-efficiency molecular sieve carrier that can be regenerated at high temperature improves the efficiency by 40% compared with similar activated carbon. It is widely used in the fields of adsorption, separation, catalysis and environment. It is more suitable for the treatment of organic waste gas with large air volume and low concentration.

Prominent Advantages of Honeycomb Zeolite Molecular Sieve

1.Strong adsorption selectivity. The pore size of molecular sieve is neat and uniform, and it is also an ionic adsorbent,therefore, it can selectively adsorb according to the size and polarity of molecules, effectively remove ethylene and propylene from saturated hydrocarbons and acetylene from ethylene, which is determined by its strong polarity.

2.Strong adsorption capacity. Even if the composition concentration of the gas is very low,it still has adsorption capacity.

3.It is less affected by temperature and still has great adsorption capacity at higher temperature, while other adsorbents are greatly affected by temperature.

4.It can be regenerated at high temperature, with high regeneration efficiency and high safety.

5.Strong toxicity resistance and good thermal stability.

Key Properties and Selection Criteria

⋅Pore Size: Determines molecular selectivity; for example, 4A excludes larger molecules, while 13X allows entry of bulky molecules.

⋅Adsorption Capacity: High surface area (often >1000 m²/g) and pore volume enable efficient adsorption, with performance varying by zeolite type (e.g., Zeolite X has a pore volume of ~0.5 cm³/g).

⋅Stability: Zeolites with higher silica-aluminum ratios (e.g., ZSM-5, Zeolite Y) offer better thermal and acid resistance, crucial for harsh industrial conditions.

⋅Applications: Span gas drying, liquid purification, catalysis (e.g., cracking, isomerization), and environmental control (e.g., CO₂ capture).

Product Applications

Common Types and Applications

⋅4A Molecular Sieve: Has a pore size of 4 Å (angstroms), effectively adsorbing small molecules like water, methanol, ethanol, hydrogen sulfide, carbon dioxide, ethylene, and propylene. It does not adsorb molecules larger than 4 Å, such as propane. This type is commonly used for drying natural gas and oilfield associated gas.

⋅5A Molecular Sieve: Features a pore size of 5 Å, often used in the separation of isoparaffins (e.g., in petroleum refining) and for desulfurization and CO₂ removal in natural gas processing.

⋅13X Molecular Sieve: With a larger pore size (about 10 Å), it is employed in air purification to remove water and carbon dioxide. It is also used in hollow glass units to absorb moisture and organic residues, maintaining clarity and structural integrity.

⋅ZSM-5 Zeolite (MFI type): Known for its high silica-aluminum ratio, ZSM-5 exhibits excellent acid stability and catalytic activity. It is used in petrochemical cracking processes and has strong anti-corrosion properties against acids like HCl, HNO₃, H₃PO₄, and H₂SO₄ (except HF), making it suitable for corrosive environments.

⋅Other Types: Includes low-silica zeolites (e.g., Zeolite A and X) with high cation exchange capacity for drying polar molecules, and intermediate-silica zeolites (e.g., Zeolite Y) for catalytic cracking due to improved thermal and hydrothermal stability.

Product Parameters

Note: It can be supplied according to the special requirements of users.

| Performance | Micropore | Mesoporous |

| Overall Dimension | 100*100*100 | 100*100*100 |

| Number of Holes (CM-2) | 16 | 16 |

| Hole Wall Thickness (MM) | 0.6 | 0.6 |

| Longitudinal Tensile Strength (MPA) | 0.8 | 0.9 |

| Transverse Tensile Strength (MPA) | 0.32 | 0.4 |

| Density (G / CM)3) | 0.50 | 0.44 |

| Specific Surface Area (M)2/ G) | >900 | >900 |

| Benzene Adsorption Rate (%) | >90% | >90% |

| Softening Point (℃) | >900 | >900 |

Related Products

Online Message